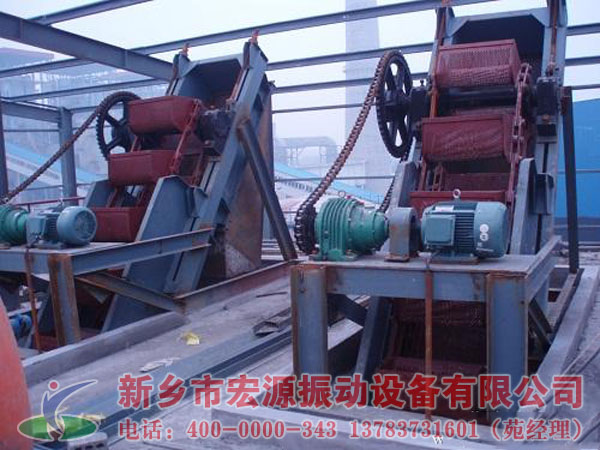

T(L)脱水/捞坑斗式提升机

T/L脱水斗式提升机概述

T/L脱水斗式提升机适用于提升洗涤后的中煤、矸石和冷却后的钙镁磷肥,T/L脱水斗式提升机也适用输送洗涤后的其他块状或颗粒状的物料,物料在提升输送过程中,可在重力作用下自行脱水。对于大块物料及水分要求不太严格的产品,如跳汰分选作业的中煤、矸石可用T/L脱水斗式提升机直接作为最终脱水设备,获得最终出厂产品。对粒度较细、或脱水不太容易、水分又要求比较严格的产品,T/L脱水斗式提升机可作为初步脱水设备。如粗煤泥回收作业中,捞坑沉淀的煤泥可先经T/L脱水斗式提升机初步脱水,再进一步用脱水筛和离心脱水机作最终脱水。

T/L脱水斗式提升机用途

T/L脱水斗式提升机分为脱水式斗式提升机和捞坑式斗式提升机,其中脱水式斗式提升机主要用于洗煤厂对跳汰洗选后的中煤或矸石提升运输和脱水,捞坑式斗式提升机则用于从捞坑沉淀池中提升大颗粒精煤和细粒煤,并使物料在提升过程中自行脱水。脱水式斗式提升机共有八种规格:T3240、T3260、T4060、T4080、T40100、T50100、T50120、T50140尾部组件的支承轴承座置于尾部壳体外面,方便检修。

T/L脱水斗式提升机主要特点:

1、T/L脱水斗式提升机结构紧凑,提升高度大,维护方便。2、T/L脱水斗式提升机运行平稳,脱水效果好。

3、T/L脱水斗式提升机每米斗容量基本按等差级数递增,有利于设备选型。